Enterprise Resource Planning (ERP) can be simplified to the core functions of managing an infinite number of multiple-complex scenarios, having precise multi-tasking skills whilst exhibiting the most detailed time management, all at the same time. You would agree, that if it was a person holding these credentials, then they would be a game changer in the organisation and worth a lot of money.

If you were to try and imagine an ERP system in an alternative context, then imagine that you were holding a birthday party for around 30 people and you decided to hire an external venue and provide food and drinks for the guests. Planning of an event like this requires you to immediately perform interrelated decisions that involve volume (quantity) and timing of materials. By estimating how many people are likely to attend, how much food and drinks will be needed, minus the amount of current food & drink (stock) that you already have, the proportion of frozen food and when exactly the frozen food needs to come out. Estimation of any food that needs to be cooked from a recipe and the calculation of multiplying by 30 to meet the demand and the timing of when to shop. When the invitations need to be prepared and sent out for RSVP’s, the availability of suitable venues and not to mention all the communication from the potential guests that have any questions.

In business, especially e-commerce, the ERP system is the latest and most significant development that has been built on the predating philosophy of the Materials Requirement Planning (MRP) system. The MRP system was originally devised in the mid-1960s to support the British Nuclear power efforts and subsequently developed further to match the integrated socio-technical system that Toyota car production had developed. The general concept around MRP was the use of calculating the product information or ‘component structure’ with the demand information to precisely form a ‘Master Production Schedule’ that was the basis of controlling and planning the perfect execution of materials arriving at the very point of manufacture, with built-in consequence factors, that saw avoiding delays in production and benefitted cashflow as stock was only called upon, on precise demand. In the 1970s the MRP system witnessed a radically overhaul that changed the basic planning and control mathematics of MRP with a turbo injected boost of ‘computer power’ as the ERP system became part of the early game changers that kicked starting the digital revolution.

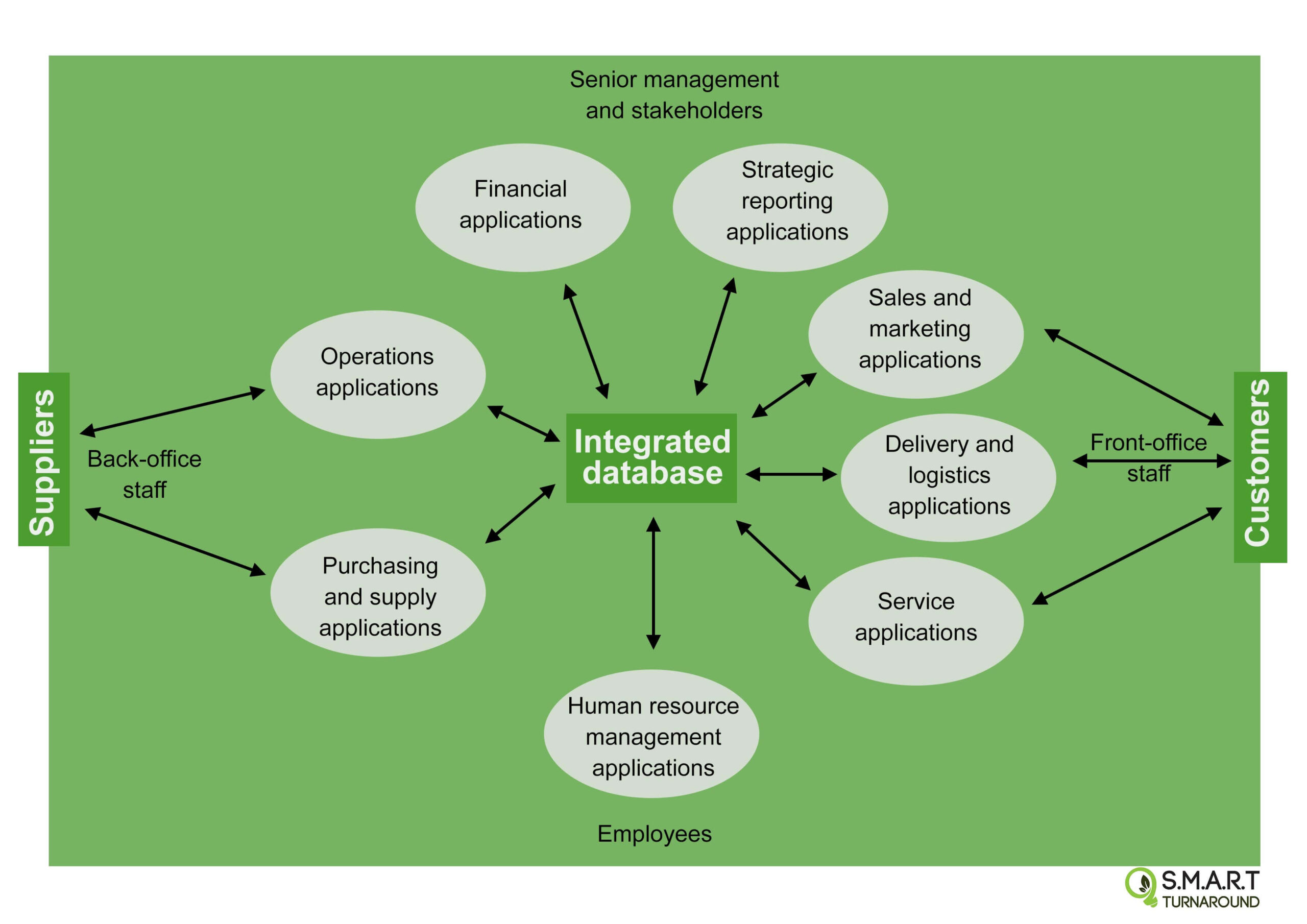

Figure 1: The Holistic view of an organisational ERP system

Through development, the ERP system is now widely acknowledged as a sophisticated tool that integrates all departments and all functions within a whole organisation into one single computer system that can serve all departments and all personnel. By housing all departments into a single network of communication allows transparency across the whole spectrum, as figure 1 shows the from sales and marketing, multiple warehousing, inventory control, supply chain management, manufacturing, human resources, accounts, finance and strategic reporting with all levels of management control that meets the needs for every department without duplication of information.

An unlikely benefit of allowing the transparency of an integrated system and database manipulation is the immediate reflection of any consequences of decisions that are taken in one part of the organisation that will always be shown in the planning and control system of another part of the business. This is recognised with multiple warehousing and stock control that may be on different continents or the accounts position of a customer before dispatching of goods and the transparency of a CRM system that can traverse across the world to ensure that information is accurate and up to date as all information is updated in real time by those who use it. However, the real clever abilities are the streamlining of processes that reduces errors and saves money with the wider integration with other ERP systems of supply chains that can work in collaboration to organise an effective stock movement, logistics and purchasing ordering efficiencies all of which save time and money and reduce mistakes. This, of course, will only ever be truly effective when more and more businesses accept the benefits of ERP and trust the collaboration.

By its very nature, an ERP system directly addresses organisational fragmentation and therefore the process of integration can take a period of time to achieve as it is a difficult system to meet the needs and expectations of cross organisational boundaries, that have to ensure the correct functionality of the overall business. Furthermore with the concept of moving everybody into a single integrated system that operates within a single database will invariably create resistance to change, which management will need to manage carefully by articulating a clear business vision, outlining achievable goals and timeframes, build a positive user acceptance through comprehensive training and clear communication. Concluding in a requirement for owner/managers to not only understand the amazing benefits an ERP system can bring to a business but equally to understand the levels of complexities that are also associated with the implementation and that a full and comprehensive consultation is required before embarking on an ERP project.